Secret Steps in the Regenerated Transformer Oil Treatment Process

Secret Steps in the Regenerated Transformer Oil Treatment Process

Blog Article

Cost-efficient and Eco-Friendly Transformer Upkeep With Regenerated Oil

The integration of restored oil in transformer maintenance offers an engaging method for companies seeking to improve both cost-efficiency and eco-friendliness. By making use of oil that preserves efficiency requirements similar to virgin choices, organizations can considerably decrease operational expenses while at the same time reducing their environmental effect.

Understanding Regenerated Oil

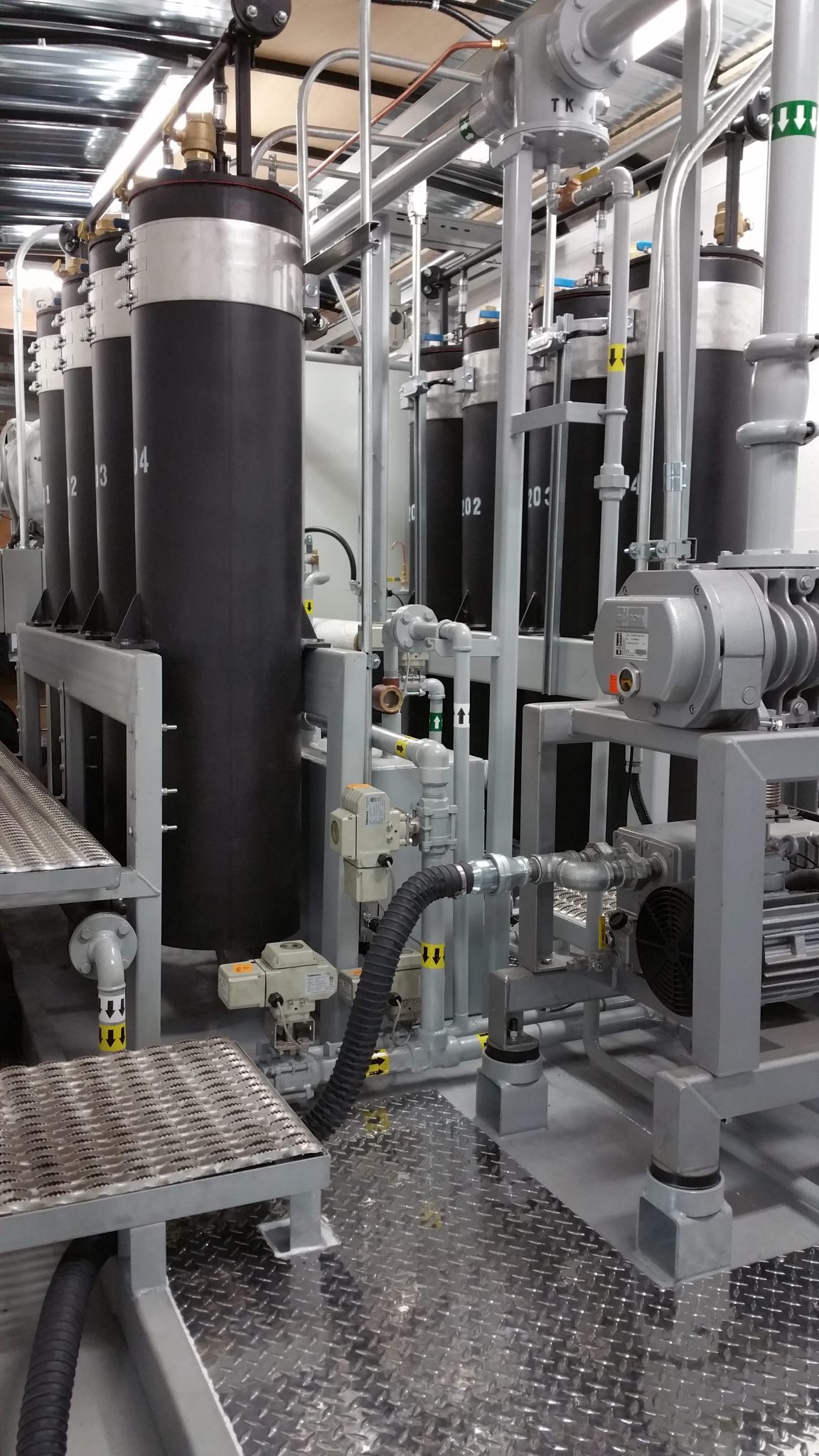

Restored oil, commonly described as re-refined oil, is an important component in the upkeep of transformers, supplying both ecological and economic benefits. This oil is obtained from used mineral oils that have gone through an extensive purification procedure, efficiently removing pollutants and restoring the oil to a top quality comparable to virgin oil. The regrowth process typically entails a number of phases, consisting of physical separation, chemical treatment, and purification, ensuring that pollutants such as sludge, water, and heavy metals are eliminated.

The application of regrowed oil in transformers is vital for optimizing efficiency and prolonging tools life expectancy. Top quality re-refined oil maintains its dielectric homes, guaranteeing effective insulation and stopping electrical failures. Furthermore, it has outstanding thermal conductivity, which aids in handling the operational temperature levels of transformers, inevitably enhancing their integrity and effectiveness.

Additionally, embracing regenerated oil not just sustains cost-efficient maintenance techniques but likewise minimizes the demand for brand-new oil manufacturing, thereby conserving natural deposits. Transitioning to re-refined oil is a smart option for organizations aiming to preserve high operational requirements while concurrently taking care of spending plan restrictions. Comprehending the buildings and benefits of restored oil is vital for notified decision-making in transformer upkeep methods.

Environmental Benefits

Using regenerated oil in transformer upkeep provides considerable environmental advantages that add to sustainable methods within the power market. One of the primary advantages is the decrease of waste oil disposal, as regenerated oil is originated from the recycling of used transformer oil, considerably lowering the quantity of unsafe waste produced. This process aids reduce the environmental dangers connected with improper disposal techniques, which can lead to dirt and water contamination.

In addition, the regeneration process conserves natural sources by minimizing the need for brand-new base oil production - Transformer Oil Regeneration Process. This preservation effort not just reduces the extraction impact on environments yet also lowers the carbon impact linked with oil manufacturing. By taking on regenerated oil, companies can enhance their dedication to environmental stewardship and straighten with worldwide sustainability goals

Furthermore, making use of restored oil improves the overall performance of transformers, leading to lowered power losses and reduced greenhouse gas discharges. As the energy sector increasingly deals with stress to lessen its environmental impact, welcoming regrowed oil stands for an aggressive technique to accomplishing both operational and environmental goals. In summary, the environmental benefits of making use of regenerated oil are diverse, promoting a healthier earth while supporting the energy industry's transition towards sustainability.

Price Cost Savings and Efficiency

Using regenerated oil in transformer upkeep can cause substantial price financial savings and enhanced functional performance for energy companies. Regenerated oil, created via sophisticated purification processes, uses similar efficiency to new oil at a portion of the price. By recycling oil that would certainly or else be thrown out, business can lower their getting expenditures while decreasing garbage disposal costs.

In addition, the prolonged life cycle of regrowed oil translates to lowered regularity of oil changes, causing lower labor prices and reduced downtime for upkeep activities. Regenerated Transformer Oil. This not only improves operational performance but likewise allows for a much more streamlined upkeep schedule, allowing firms to designate sources more successfully

In addition, using regrowed oil can lead to lower insurance policy costs due to its eco pleasant profile. As power firms face increasing analysis regarding their ecological effect, taking on sustainable practices such as using regrowed oil can boost their track record and possibly bring in financial investment.

Eventually, the integration of regrowed oil into transformer maintenance techniques offers a tactical opportunity for energy companies to accomplish substantial expense savings while promoting functional efficiency, thereby aligning economic efficiency with environmental duty.

Contrast With Standard Oils

While conventional oils have long been the criterion in transformer maintenance, a comprehensive comparison discloses that regenerated oils supply several benefits that improve performance and sustainability. Traditional mineral oils, while sites effective, often present environmental risks, such as contamination and disposal problems. On the other hand, regenerated oils are originated from recycled products, substantially minimizing their ecological impact.

Among the key differentiators is the chemical security of regenerated oils. They generally show premium oxidative security, which equates to longer service life and reduced frequency of oil changes. This characteristic not just improves transformer efficiency but additionally reduces downtime and upkeep prices. In addition, regenerated oils frequently consist of lower degrees of hazardous ingredients, making them a safer choice for the environment and both devices.

In addition, regenerated oils supply outstanding dielectric homes, making sure reliable electrical insulation. This top quality is crucial in preserving transformer performance under see this page varying operational problems. Making use of regenerated oils likewise aligns with worldwide sustainability objectives, appealing to companies committed to reducing their carbon footprint. Overall, the advantages of regenerated oils over conventional oils highlight their potential to reinvent transformer maintenance practices, offering a much more liable and reliable choice.

Implementation in Upkeep Practices

Once the evaluation is complete, a tailored plan for transitioning to restored oil needs to be developed, thinking about aspects such as compatibility with existing products and functional conditions. Educating for maintenance personnel is essential, as they should recognize the distinct buildings of regenerated oils and how to manage their application properly.

Implementing an extensive surveillance program will certainly help with the evaluation of efficiency metrics post-implementation, making sure the restored oil satisfies the required functional standards. Reclaimed Transformer Oil. Furthermore, developing a normal maintenance routine will certainly assist in identifying potential concerns early and permit punctual restorative actions

Final Thought

In final thought, the fostering of restored oil for transformer upkeep offers a feasible service that lines up economic advantages with environmental sustainability. By decreasing prices associated with oil adjustments and waste disposal, while at the same time expanding the lifespan of devices, companies can improve functional efficiency. The shift to regrowed oil not just mitigates ecological effects however also supports broader sustainability purposes, making it a sensible option for contemporary upkeep techniques in the power market.

Regenerated oil, often referred to as re-refined oil, is a crucial element in the upkeep of transformers, giving both ecological and financial benefits. This oil is derived from made use of mineral oils that have actually undergone a comprehensive filtration process, properly eliminating impurities and bring back the oil to a high quality equivalent to virgin oil.Additionally, adopting regrowed oil not just sustains affordable upkeep techniques however likewise decreases the need for new oil production, thereby preserving natural sources. One of the key benefits is the reduction of waste oil disposal, as regenerated oil is derived from the recycling of used transformer oil, considerably lowering the quantity of hazardous waste created. Check This Out Regenerated oil, generated via sophisticated filtration procedures, uses comparable performance to new oil at a portion of the cost.

Report this page